3D PRINTING

Focusing on low volume production and one-offs, offering affordable prices and advice on the most appropriate 3D printing material for your application.

Quick turnaround

Do you have a design file that you would like to 3D print, but don’t have a 3D printer of your own?

I can provide efficient 3D printing with a quick turnaround. The maximum size for a 3D print is 255x205x205 with a print resolution of 0.1mm.

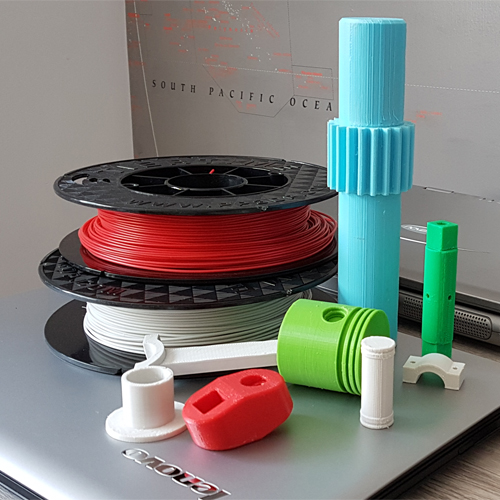

3D Printed components

3D Printed assembly

What is 3D Printing?

3D Printing is a process that can produce physical objects direct from 3-dimensional CAD data. The process works by ‘slicing’ the data geometry into many 2-dimensional cross sectional layers, and re-constructing them successively upward within the printer. When the part has completed construction, it is then removed from the printer and cleaned up to produce the finished part. 3D printing enables you to produce complex, functional shapes using less material than traditional manufacturing methods which makes it the ideal solution for prototype work.

How much does 3D Printing cost?

We charge for 3D printed models based on a formula that takes into consideration build time, setup and labour time. For data that contains errors there may be an additional charge for the time required to repair the file for printing.

What file format is used for 3D Printing?

We require your 3D Model as an STL file, nearly all CAD systems are now capable of saving or exporting your 3D creation as STL. Ensure that the STL output type is set to binary which saves on time and file size.

How long does it take?

3D printing is one of the fastest ways to prototype physical objects, but it is not instant. Large builds can take up to 20 hours, plus additional time for pre and post processing. Specifying your deadline is one of the best ways for us to prioritise your work and ensure delivery for a time suited to you.

What materials can I print in?

We use ABS or PLA plastic to produce high quality, robust parts in a range of colours.

ABS (Acrylonitrile Butadiene Styrene).

ABS is strong and has a reasonable amount of flex to it and is used in applications like LEGO and automotive bumper parts. It tends to bend rather than snap when put under pressure. Objects that might be dropped, put in hot environments or used in a rough manner are perfect for ABS. Think of knife handles, car phone mounts, phone cases and toys. It’s generally best suited for applications where strength, ductility, machinability and thermal stability are required. ABS is not biodegradable, however it is recyclable.

PLA (Polylactic Acid ).

PLA is derived from renewable resources like sugarcane or starch which makes it biodegradable, it also requires less heating to print and is less likely to warp once cooled down. You can print sharper corners and features compared to ABS. While you can still print strong objects with PLA, it tends to be a little more brittle than ABS. Rather than bouncing when dropped or struck, some printed parts may just shatter or chip. In short PLA is ideal where aesthetics and fine details are more important than strength.

To receive a quotation send the STL file to sales@teratek.co.uk so that we can identify your requirements and check the suitability of the part for 3D printing.